Embrace the future:

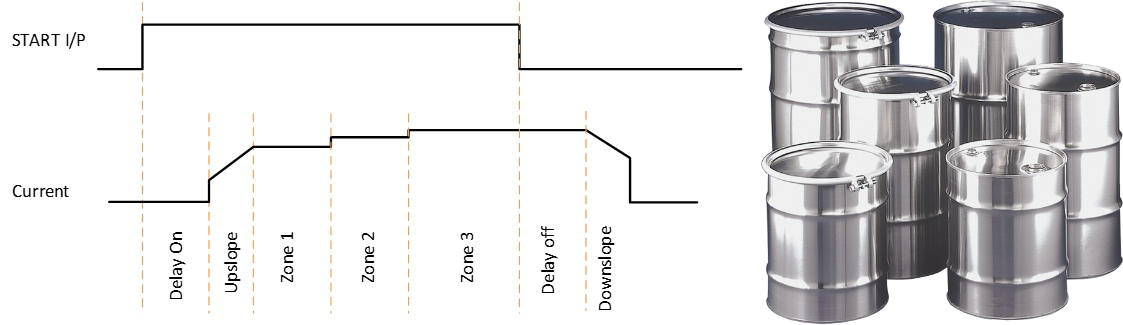

The iPAK2v2 Drum Welder Control

The Technology Benefits of the IPAK2v2D Drum Welder

- 16 Inputs /16 Outputs (Short Circuit Protected)

- Primary Current regulation

- Current Monitoring

- Data Log (Drums) 6000

iPAK2v2D-LMI-1500A-400E

This control is ideal for the steel drum industry. Where low or high speed output is required for manual and fully automatic machines.

Connect With a Technical Specialist

Complete the form to connect and discover how the iPAK2v2 Drum Welder Control can revolutionize your welding operations. Achieve welding excellence today.

Connect with us Today

Mexico

Mexico